One name is synonymous with narrow gauge locomotive restoration and new-build projects. Mark Smithers reports on progress to be seen at an open day at Alan Keef Ltd.

The name of Alan Keef Ltd will doubtless be familiar to most operators and fans of heritage railways, especially in the narrow gauge field, as its product range, which covers contemporary industrial railway equipment in addition to heritage material, has grown steadily since the company’s foundation in 1968. Well known for supplying new steam locomotives to such diverse locations as Beamish Museum’s waggonway and the locally-based Perrygrove Railway, one of the company’s most important features is that it is the proud successor to Motor Rail Ltd and Simplex Mechanical Handling Ltd and is therefore able to supply full technical back-up to Simplex locomotive owners.

The (normally) annual early autumn steam-up and open day at Alan Keef Ltd’s workshops, based at Lea near Ross-on-Wye, has consistently proved a popular event and although it did not take place in 2015 owing to other commitments, its return for the current year on September 17 was very welcome, and I was able to take advantage of the opportunity to visit the site on that occasion.

As a representative of the Simplex connection with the company’s work, the 1920-vintage 2ft 6in gauge Simplex petrol locomotive, Dalmunzie (No. 2014) was on display outside the workshops. The most iconic of the items that were present on-site for most narrow gauge enthusiasts, however, was the project to re-create the well-known Baldwin 2-4-2T of the Lynton & Barnstaple Railway. This is a project that will be familiar to visitors to Alan Keef Ltd open days and L&BR galas since 2013.

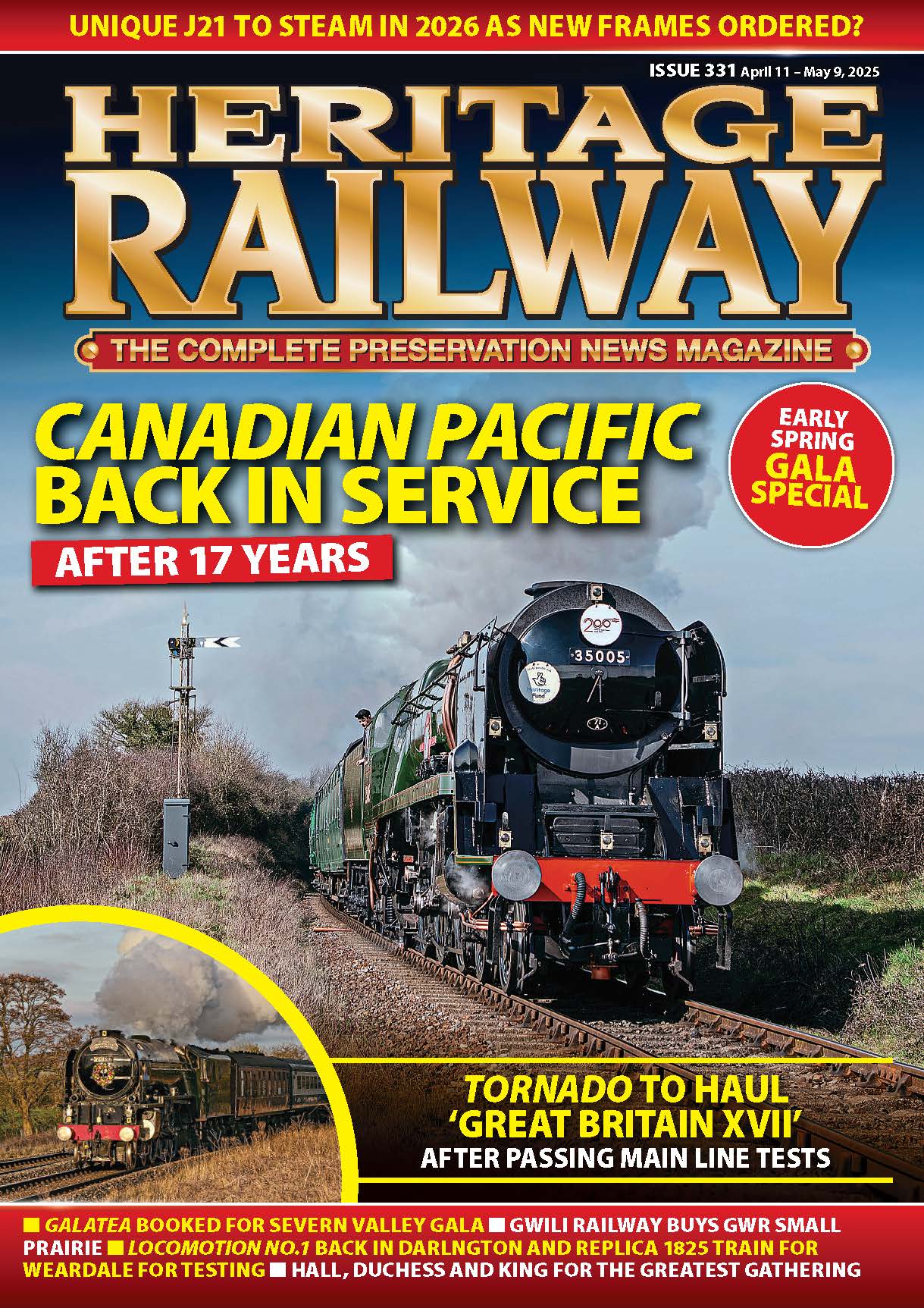

Enjoy more Heritage Railway reading in the four-weekly magazine.

Click here to subscribe & save.

The history of the original locomotive will be well known to most readers: suffice to say that its construction in the US was necessitated by the knock-on effects of the national dispute over an eight-hour working day in the engineering industry, whose employers undertook a lock-out during the period from July 1897 to January 1898.

The original Lyn was completed at Baldwin’s Philadelphia workshops in July 1898

(No. 15965) and remained in service after receiving a new Avonside-built boiler in 1907 and an overhaul at Eastleigh Works under Southern Railway ownership in 1928-9, until the closure of the railway in September 1935, being scrapped following the auction of assets that took place two months later.

Greater potential

With the resurgence of the Lynton & Barnstaple Railway as a preservation venue in more recent years, the need arose for the construction of a new locomotive for the line and Lyn was chosen as the locomotive to re-create, offering greater flexibility in relation to the Manning Wardle design used by the original undertaking (owing to a shorter fixed wheelbase) and greater potential for driver comfort as a consequence of its commodious cab. In any case, the Manning Wardle design has already been resurrected in the form of the Ffestiniog Railway’s Lyd, a locomotive that has previously visited the revived L&B.

In pursuance of the replica project, a registered charity, the 762 Club (named after the number carried by the original Lyn in SR days) was formed and erection of the locomotive has been undertaken in the Alan Keef workshops incorporating components sourced from several outside contractors, a good proportion of whom are situated in the locality of the Lynton & Barnstaple Railway. Construction of the new locomotive began in 2009, a year in which the casting of one coupled wheel and one pony wheel was undertaken. By February 2014, the remaining wheels has been cast, delivered to the Lea-based workshops, machined and put into storage.

Another important component completed by Alan Keef Ltd shortly beforehand was the smokebox saddle, an item that would, in accordance with normal Baldwin practice, have been comprised of two castings, right and left-handed, bolted together. On the replica, it has been fabricated and it is very important in that it forms the effective reference point for the assembly of the mainframes and location of the necessary fixing holes.

Although the replacement Lyn will re-create the authentic appearance of the original locomotive as it returned to the railway from Eastleigh Works in 1929, a number of refinements will be incorporated to suit 21st century standards, thereby increasing efficiency and allowing a haulage capacity some 50% greater than its predecessor. Design work on the new locomotive has been undertaken by the Cambridge-based team of Ian Gaylor and Mike Nelson, with John Scott acting as independent consultant overseeing the work.

Design alteration

The locomotive’s boiler, which was on display outside the workshops, was built by Bennett’s Boilers Ltd of Highbridge, Somerset and received its first hydraulic test (to 500psi, or twice the maximum working pressure) on June 5, 2013. In addition to the normal fire tubes, the new boiler has 11 superheater flues and a machined superheater header.

Following a design alteration to the dome in order to obtain better access to the regulator components (necessitating a further hydraulic test), and the completion of the smokebox, door, chimney, superheater items and other fittings, the boiler was moved to Alan Keef Ltd for storage during the following year. A particularly pleasing touch is that the new whistle has been made from castings donated by Emile Badawy, a driver on Australia’s 2ft 6in gauge Puffing Billy Railway near Melbourne. This railway operates Australian-built NA class 2-6-2Ts of Baldwin design with a recognised family resemblance to Lyn and their whistle design is likely to be the closest that one can reasonably get to the original.

Following a meeting towards the end of 2013, an order was placed for fabricated cylinder blocks with F W Frost Ltd of Norwich. Once again there were conflicting demands on the design team as modern constructional and performance requirements dictated the need for fabricated cylinders with piston valves, while the original locomotive was fitted with cast cylinders and steam chests of the slide valve variety. A design was therefore produced which satisfied the modern requirements yet retained the appearance of the cylinder arrangements found on the original Lyn; no mean feat in itself.

The fabrication and assembly and machining of the cylinders was an intricate process, but it passed off without major incident save for the fact that one of the valve liners (which, as with the cylinder liners, were frozen to shrink-fit them into the main structure using liquid nitrogen) expanded into its appointed recess before reaching its intended position. The incorrectly-fitted liner had to be machined out and a replacement liner made and fitted; a process that was duly accomplished successfully.

Following pressure testing and final honing, the completed cylinders, with covers, pistons and valves, were finally sent to Alan Keef Ltd in November 2015. The bunker and side tanks for the new Lyn have been made by Babcock International in Appledore, once again fairly local to the L&B. These were completed and delivered to Lea in 2014.

Put on display

Babcock also supplied many of the frame components, and following some drilling work at Lea and other machining to profile in South Wales, these were sent to Lowther’s of Whitchurch near Ross-on-Wye, who also supplied the materials and initial workmanship for the side mainframes (some 80mm in thickness), for fabrication prior to return of all of the frame-related items to Lea. They were first put on display in assembled state during a special 762 Club open day at Alan Keef’s works on November 28, 2015, (staged as a consequence of the normal open day not taking place that year as previously mentioned).

The crankpins and webs were made on site at Lea, allowing the coupled wheelsets to be fully assembled, including the axleboxes, by January 2015, and it must be remembered that unlike the original locomotive, the axleboxes on the new Lyn are of the SKF roller-bearing variety and hence cannot be split for maintenance purposes in the way that those of the traditional variety can. It is therefore important that they satisfy the demands placed upon them and attain good longevity in service, as replacement would not be an easy process. It is anticipated that these bearings will have a service life of 10 years between heavy general overhauls with a calculated risk of failure of 1-3% assuming good track alignment.

Similar bearings are used throughout the chassis, including for the pony truck wheelsets, and when compared to the original locomotive, the new pony trucks have employed a considerable measure of redesign work. While the traditional pattern of Bissell truck construction is retained on the leading truck, ‘swing’ control is not accomplished by means of springing, but two cam-actuated bellcranks (one for each side of the longitudinal centre of the truck’s swing) are employed, attached to longitudinal shafts on the truck and each actuated by a curvilinear profiled vertical runner attached to the locomotive’s chassis. Side control is accomplished in a similar manner on the rear pony truck, but owing to the desire to obtain as deep a firebox as possible, on this truck there is no Bissell ‘A’-frame.

In place of this arrangement, a system of levers, once again cam-guided, is employed with two main fulcra (one each side of the locomotive) being mounted on the inside surface of the rear bufferbeam. Other modern refinements incorporated into the new Lyn include provision for improved draughting arrangements including the use of the Lempor four-nozzle blastpipe system, a firehole door employing adjustable air inlets to control airflow into the fire from above, and a suitably revised ashpan design.

Vacuum braking will be employed for the main train control: in addition the new locomotive will have a steam brake, using a cylinder supplied by the Ffestiniog Railway, to augment its customary hand braking system. With all of Lyn’s components, save for a few ‘cosmetic’ items and a few items that cannot be made until final assembly, it is currently hoped that Lyn will make its public debut at Woody Bay on May 13, 2017.

Exciting prospect

Up to the time of writing, over £500,000 has been raised (mainly by sales of memberships of the 762 Club and component sponsorship), towards the cost of the locomotive’s construction and in order to raise the £75,000 to finance the last stage of construction, the Final Assembly Appeal has been launched (further details may be found on the 762 Club section of the L&BR website) and the entry of Lyn into service will surely be an exciting prospect for all fans of the British narrow gauge preservation scene.

Lyn was not the only classic narrow gauge ‘new build’ project on display at the open day as in the spring of 2007, following a poll of Corris Railway Society members, the decision was taken to build a second new steam locomotive for the revived section of the railway based on the 1878 Hughes Locomotive and Tramway Works design as exemplified by the surviving original, Sir Haydn, on the Talyllyn Railway.

Drawings for the new locomotive were completed by the Corris Railway’s boiler inspector, Graham Morris and his colleague David Potter in September 2009 following a thorough survey of Sir Haydn and work on the new locomotive, to be No. 10 in the Corris fleet, is now very advanced. In addition to retaining the pony truck on No. 10 which was fitted to all of the original three class members in order to improve riding characteristics, it was decided to raise the cab roof level when compared to the original three locomotives to provide more comfort for the locomotive crew.

This modification will be made in a manner more consistent for the original locomotives’ cab profile immediately prior to GWR days than is currently to be found on Sir Haydn. Although the boiler for No. 10, which was completed by Israel Newton near Bradford in 2012, was transported to Maespoeth during the late summer of that year, much of the work on the locomotive’s chassis has been undertaken at Lea and the fruits of this labour were on display at the open day.

The most significant items in evidence were the mainframe and horn guide assembly; the axleboxes for the coupled wheelsets; the coupled axles and associated crankpins and the castings for the wheel centres. These are illustrated in the accompanying photographs. As with the L&B Lyn project, much of the finance for the Falcon Locomotive Fund (as the project to build No. 10 is known) has been raised

by the sponsorship of individual components, and although not fully complete at the

time of writing, this process is certainly well advanced and it should not be too long before we see one of the original pattern of Corris Railway 0-4-2STs regularly at work in the Dulas Valley once more.

Approximately £150,000 has been raised towards the construction of No. 10 and currently estimates put the required amount to be raised to complete the project at about £250,000, which is not intended to be financed by borrowing. No manufacturer has yet been lined up for the cylinders, an issue that will be

dealt with when suitable finance becomes available.

Beamish Museum apart, standard gauge projects are relatively rare in the grand scheme of Alan Keef Ltd’s endeavours, but one interesting item that was on display was the project to re-create the four-wheel Baguley-Drewry railcar (No. 1647/1927) used on the Ryde Pier Tramway on the Isle of Wight. The replica, which is allocated Alan Keef works No. 98R of 2016, contains some parts of the original’s surviving chassis, including the wheelsets, but it will be fitted with a modern Perkins 404D-22T diesel engine and a JCB transmission. When completed, it will be operated on the Isle of Wight Steam Railway in conjunction with a replica trailer.

Another unusual project being undertaken on site is the restoration for a Dutch customer of a metre gauge 0-4-0T enclosed tramway locomotive (Henschel No. 5276 of 1899) originally built for use in the German city of Kassel and converted in 1940 to a fireless locomotive for use in a paper mill.

This locomotive, which is characterised by its cylinders being placed between the mainframes with overhead steam chests (an arrangement necessitated by the track gauge), has received rather rough treatment during its working life as evidenced by the degree of distortion found in its mainframes during the restoration process. It is fitted with drawgear capable of handling different types of rolling stock as can be seen in the accompanying illustration.

Popular attraction

The 2ft gauge railway that runs in the outdoor part of the company’s premises is a popular attraction during open days and at this year’s event, the two steam locomotives in action were Graham Morris’ Kerr Stuart ‘New Type Wren’ class 0-4-0ST Peter Pan (No. 4256 of 1922) and resident ‘Bullhead’ Bagnall 7in by 12in 0-4-0ST Woto (No. 2133 of 1924).

The pair took it in turns to haul passengers in a Hayfield and Whaley Bridge Light Railway four-wheel carriage on the line that links the main road frontage with the locomotive sheds. Peter Pan’s saddle tank is showing signs of wear and a replacement item is currently under construction. Another Alan Keef favourite, replica De Winton pattern 0-4-0VBT Taffy was on display, but sadly out of service awaiting retubing.

All in all, the day’s proceedings provided an important opportunity, continuing in the charitable fundraising spirit of previous open days, to raise some £4600 (from the £6 per head admission fee) for a local church and a welcome opportunity for Alan Keef Ltd to showcase its products as well as providing much entertainment for the myriad of enthusiasts present.

Thanks are therefore due to Alan, the company’s chairman, his son Patrick (managing director), and daughter Alice Basey (chief design engineer) in this connection. In addition, I would like to acknowledge the help of Jon Pain, Geoff Hill and Peter Best of the L&BR and David Coleman and Peter Guest of the Corris Railway for their assistance in the preparation of this feature.

Read more News and Features in Issue 232 of HR – on sale now!

Archive enquiries to: Jane Skayman on 01507 529423 – [email protected]

Advert

Enjoy more Heritage Railway reading in the four-weekly magazine. Click here to subscribe.

Enjoy more Heritage Railway reading in the four-weekly magazine. Click here to subscribe.